We can provide the following product services: rock wool board, rock wool blanket, glass wool board, and glass wool roll

Specification of glass wool roll felt

Views :

Update time : 2024-03-06

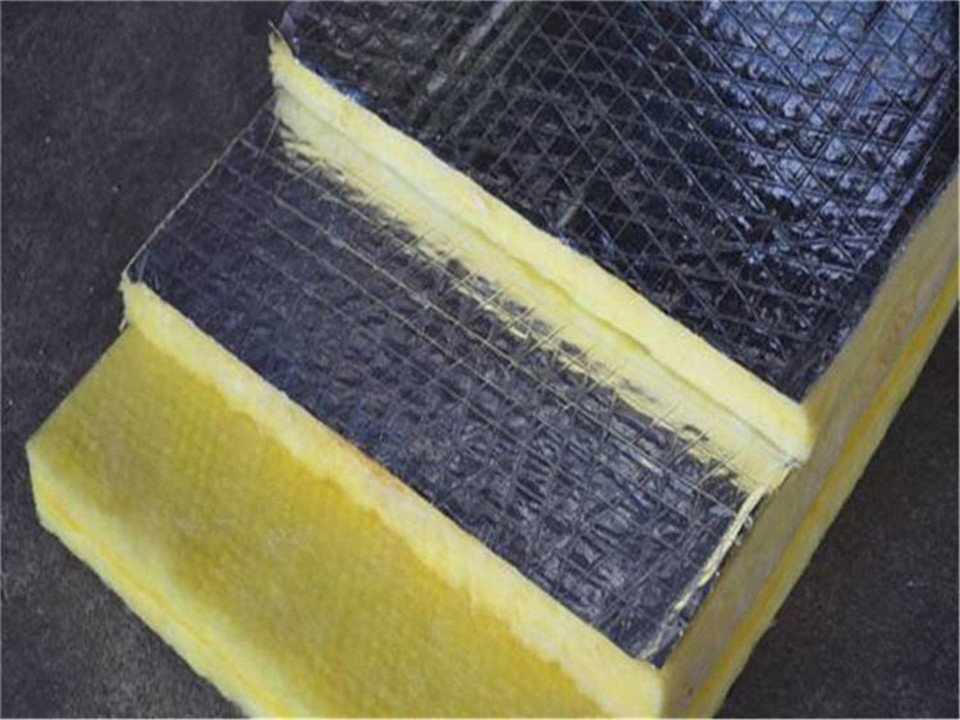

Glass wool roll felt is a type of thermal and acoustic insulation material made from glass fibers. It is commonly used in construction for its excellent insulation properties, which help in conserving energy and enhancing indoor comfort. Here's a detailed specification of glass wool roll felt:

Material Composition: Glass wool roll felt is primarily composed of fine, spun glass fibers. These fibers are manufactured from molten glass, which is then spun into a fibrous mat. The fibers are bonded together using a thermosetting resin, which enhances the strength and durability of the material.

Related News

Read More >>

Smoke prevention and exhaust g

Smoke prevention and exhaust g

03 .23.2024

It seems like you‘re asking about using glass wool boards for smoke prevention and exhaust systems. ...

Burning performance level of g

Burning performance level of g

03 .23.2024

The burning performance of glass wool board, like any other material, depends on its composition and...

Insulation Related Product-Gla

Insulation Related Product-Gla

03 .23.2024

Glass wool board is a type of insulation material made from recycled glass fibers. These fibers are ...

Can glass wool board replace f

Can glass wool board replace f

03 .23.2024

Glass wool board can indeed be used as a fireproof material in certain applications. Glass wool is a...