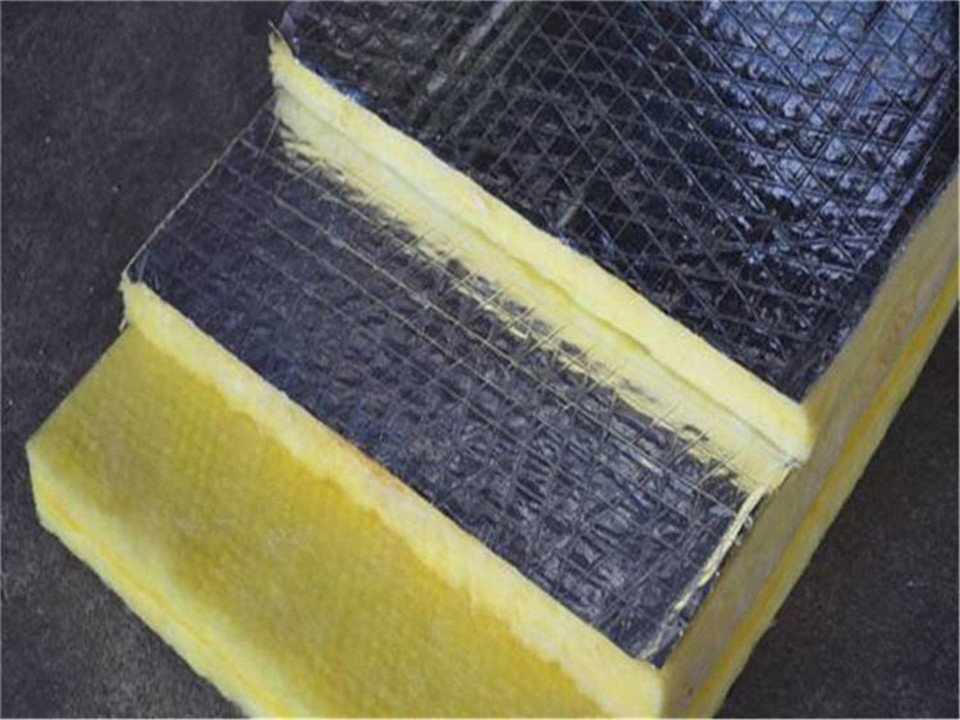

We can provide the following product services: rock wool board, rock wool blanket, glass wool board, and glass wool roll

Calculation method for glass wool roll felt

Views :

Update time : 2024-03-11

The production process of glass wool roll felt involves several steps, from raw material selection to the final product. Here's a detailed description of the typical manufacturing process:

Raw Material Selection:

Glass wool is made from silica sand, limestone, soda ash, and recycled glass. These materials are chosen for their thermal and acoustic insulation properties.

Melting:

The raw materials are melted in a furnace at temperatures around 1,400-1,600°C (2,552-2,912°F) to form molten glass.

Fiber Formation:

The molten glass is then spun into fibers using a process called centrifugal spinning or blowing. High-speed spinning wheels or air jets break the molten glass into fine strands.

Binding Agent Addition:

Related News

Read More >>

Smoke prevention and exhaust g

Smoke prevention and exhaust g

03 .23.2024

It seems like you‘re asking about using glass wool boards for smoke prevention and exhaust systems. ...

Burning performance level of g

Burning performance level of g

03 .23.2024

The burning performance of glass wool board, like any other material, depends on its composition and...

Insulation Related Product-Gla

Insulation Related Product-Gla

03 .23.2024

Glass wool board is a type of insulation material made from recycled glass fibers. These fibers are ...

Can glass wool board replace f

Can glass wool board replace f

03 .23.2024

Glass wool board can indeed be used as a fireproof material in certain applications. Glass wool is a...