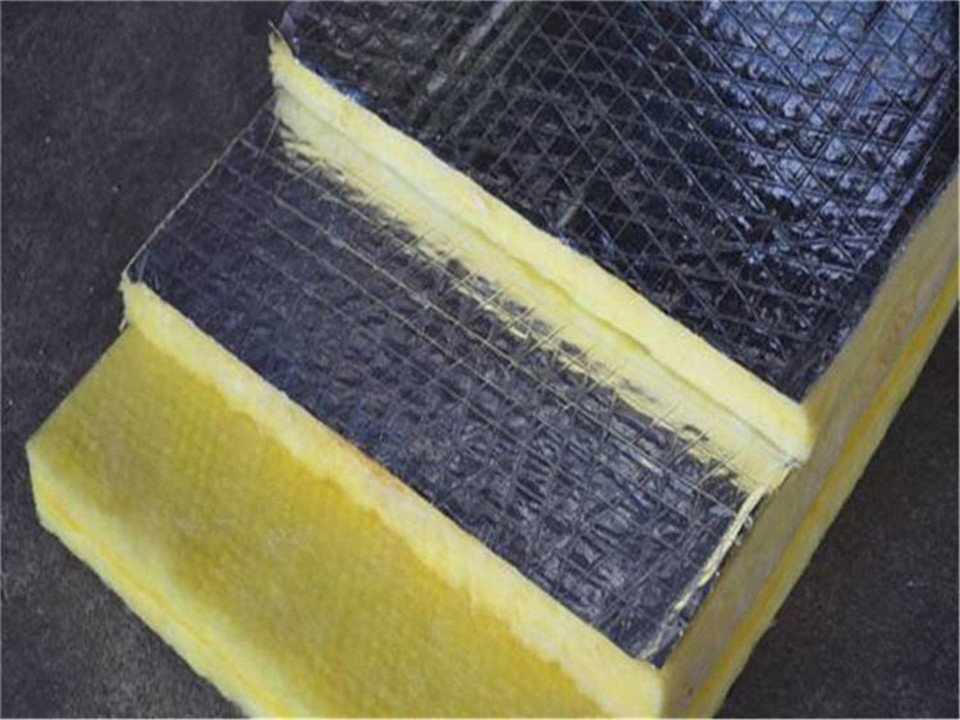

We can provide the following product services: rock wool board, rock wool blanket, glass wool board, and glass wool roll

Fire resistance limit of glass wool roll felt

Views :

Update time : 2024-03-13

Glass wool roll felt, a common insulation material, typically exhibits a high level of fire resistance, making it a preferred choice in construction and industrial applications where fire safety is paramount. The fire resistance limit of glass wool roll felt is determined by various factors including its composition, density, thickness, and any additional fire-retardant treatments it may undergo.

Glass wool itself is inherently non-combustible, as it is primarily composed of recycled glass fibers bonded together using a thermosetting resin. These fibers are capable of withstanding high temperatures without igniting. Additionally, the high density and compact structure of glass wool contribute to its ability to resist flames and prevent the spread of fire.

However, while glass wool is naturally fire-resistant, it's important to note that its fire resistance limit may vary depending on the specific product and its intended application. Manufacturers often conduct rigorous testing to determine the fire performance characteristics of their glass wool products, including tests for flame spread, smoke development, and heat release rate.

In many regions, building codes and regulations stipulate minimum fire safety standards for construction materials, including insulation materials like glass wool. These standards may specify requirements such as flame spread ratings, smoke development ratings, and fire resistance durations under standardized testing conditions.

Related News

Read More >>

Smoke prevention and exhaust g

Smoke prevention and exhaust g

03 .23.2024

It seems like you‘re asking about using glass wool boards for smoke prevention and exhaust systems. ...

Burning performance level of g

Burning performance level of g

03 .23.2024

The burning performance of glass wool board, like any other material, depends on its composition and...

Insulation Related Product-Gla

Insulation Related Product-Gla

03 .23.2024

Glass wool board is a type of insulation material made from recycled glass fibers. These fibers are ...

Can glass wool board replace f

Can glass wool board replace f

03 .23.2024

Glass wool board can indeed be used as a fireproof material in certain applications. Glass wool is a...