We can provide the following product services: rock wool board, rock wool blanket, glass wool board, and glass wool roll

How to use centrifugal glass wool roll felt

Views :

Update time : 2024-03-16

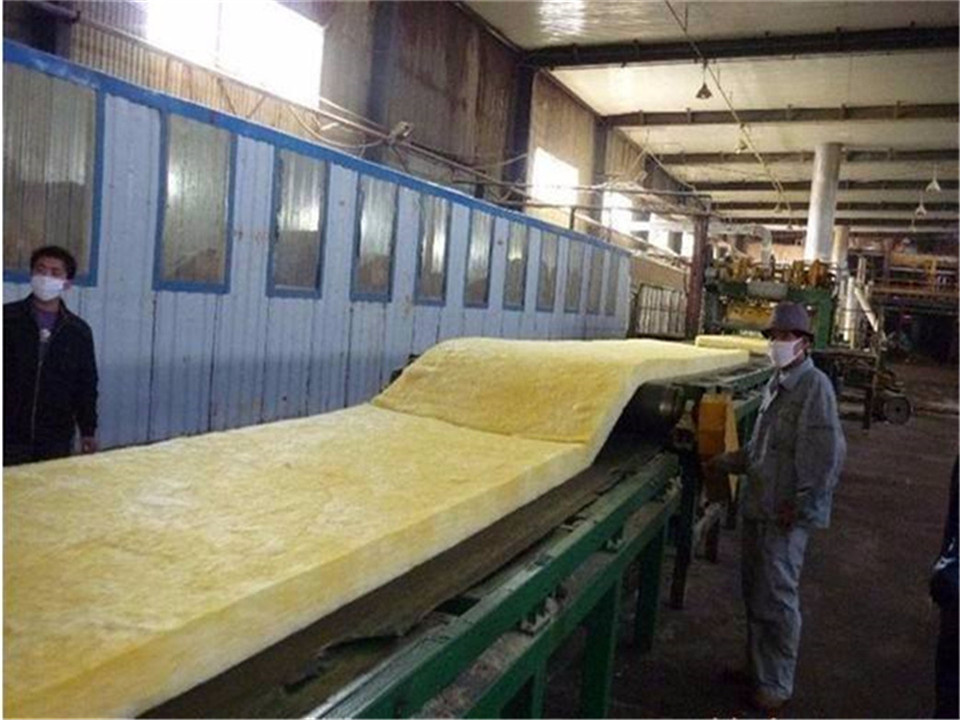

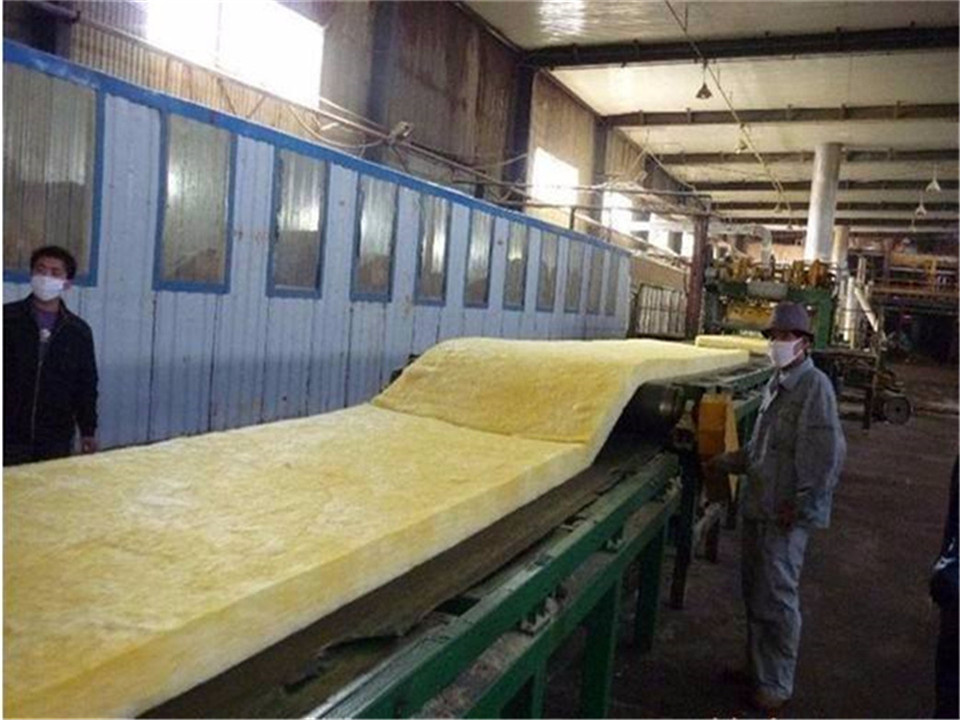

Centrifugal glass wool roll felt is a versatile insulation material commonly used in various applications such as thermal insulation, soundproofing, and as a barrier against moisture and fire. It's made from fine glass fibers spun from molten glass and then processed into rolls for easy installation. Here's a detailed guide on how to use centrifugal glass wool roll felt:

Safety Precautions:

Before handling centrifugal glass wool, ensure you have appropriate safety gear including gloves, goggles, long sleeves, and a mask to protect against irritation from the fine fibers.

Surface Preparation:

Ensure the surface where you plan to install the glass wool is clean, dry, and free from any debris. This will ensure proper adhesion and effectiveness of the insulation.

Measurements and Cutting:

Measure the area where you intend to install the glass wool rolls. Use a sharp utility knife or scissors to cut the rolls to the required dimensions. It's crucial to measure accurately to minimize wastage and ensure proper coverage.

Installation:

Start by unrolling the glass wool material carefully. Avoid pulling or stretching the material excessively, as this can affect its insulating properties.

Place the glass wool rolls snugly into the desired spaces. For example, between wall studs, ceiling joists, or roof rafters. Ensure there are no gaps or spaces left uncovered to maximize insulation efficiency.

If installing in walls or ceilings, gently press the material into place, ensuring it fills the cavity evenly without compression. Over-compression can reduce its effectiveness.

When installing in roofs, ensure the material is laid evenly over the rafters, covering the entire surface area without leaving any gaps.

Related News

Read More >>

Rock Wool in Tagalog Wikipedia

Rock Wool in Tagalog Wikipedia

09 .06.2024

Rock wool, also known as mineral wool or rock mineral fiber, is a type of insulation material made f...

Rock Wool Composite Board: Rev

Rock Wool Composite Board: Rev

09 .06.2024

In the realm of contemporary construction, the demand for sustainable and innovative materials is ev...

Rock wool, which finds its ori

Rock wool, which finds its ori

09 .03.2024

In Tagalog, the term for rock wool often translates to "kalamay ng bato" or "bato kal...

Rock Wool Insulation Board: A

Rock Wool Insulation Board: A

09 .03.2024

Rock wool insulation board has gained significant attention in the construction and building materia...