The reason why rock wool boards are expensive

Rock wool board's relatively high price can be attributed to several main reasons:

1. Manufacturing Process: The production of rock wool boards involves high-temperature melting of natural rocks, followed by fiberization of the molten material to create a unique fibrous structure. This manufacturing process requires specialized equipment and high-temperature environments, increasing production costs.

2. Raw Materials: The raw materials for rock wool boards are typically natural rocks such as basalt or diabase. The extraction, transportation, and processing of these natural rocks, often obtained from underground, contribute to the overall cost.

3. Technical Requirements: The manufacturing process of rock wool boards involves high-temperature treatment and fiberization technology. Strict control over equipment and processes is required, adding to the technical complexity and costs.

4. Performance Characteristics: Rock wool boards exhibit excellent thermal insulation, fire resistance, and other special characteristics, which can influence their price. Higher performance often comes with higher costs.

5. Environmental and Safety Standards: Rock wool boards are usually environmentally friendly construction materials, complying with relevant environmental and safety standards. Adhering to these standards requires stricter production processes and quality control, increasing production costs.

6. Economic Factors: The price of rock wool boards is influenced by market supply and demand, fluctuations in raw material prices, and other economic factors. When the supply is limited compared to demand, prices may rise.

In summary, the relatively high price of rock wool boards is mainly due to the combined impact of the complex manufacturing process, the use of high-quality raw materials, technical requirements, and performance characteristics.

Smoke prevention and exhaust g

Smoke prevention and exhaust g

Burning performance level of g

Burning performance level of g

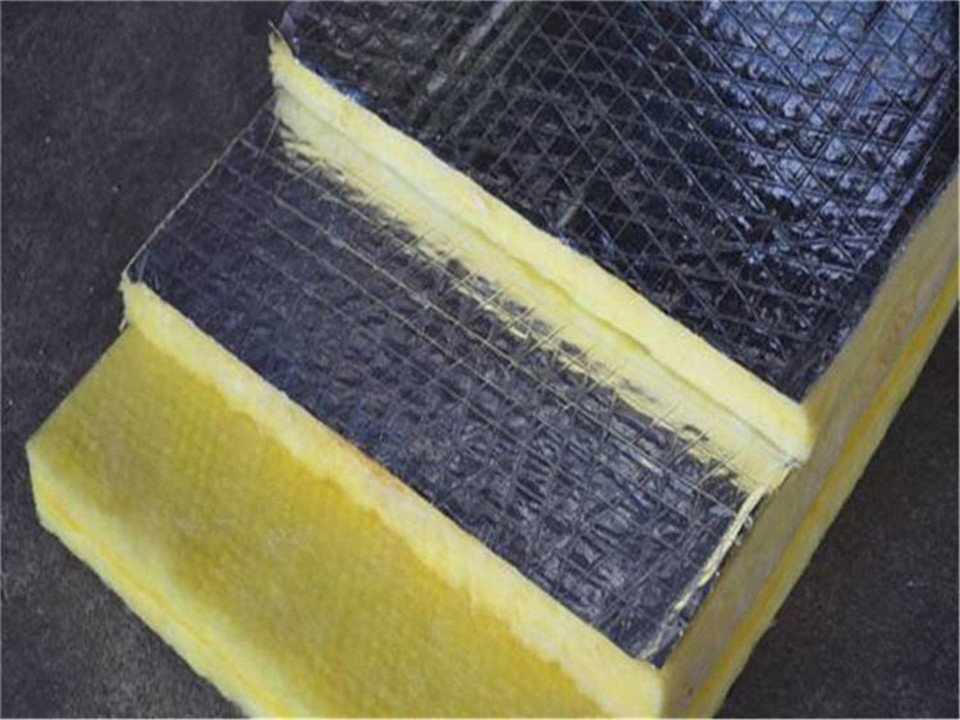

Insulation Related Product-Gla

Insulation Related Product-Gla

Can glass wool board replace f

Can glass wool board replace f