What is the production raw material of rock wool board?

The raw materials used in the production of rock wool boards mainly include natural rocks and other auxiliary materials. Here are the common raw materials used in the manufacturing process of rock wool boards:

1. Natural Rocks: The primary raw materials for rock wool boards are natural rocks, with basalt and diabase being the most commonly used types. These rocks are typically obtained through mining.

2. High-Temperature Melting Agent: In the manufacturing of rock wool boards, natural rocks undergo a high-temperature melting process. To facilitate this step, a high-temperature melting agent may be added to ensure complete melting of the rocks under high-temperature conditions.

3. Binder: To form the fibrous structure of rock wool boards, a binder is often added. These binders help in fiberizing the melted rocks and maintaining the shape of the boards during subsequent production steps.

4. Waterproofing Agents and Water-Repellent Agents (Optional): Some rock wool boards may incorporate waterproofing agents or water-repellent agents during the production process to enhance their resistance to water. This depends on the specific application and requirements of the final product.

These raw materials undergo various production processes, including high-temperature melting, fiberization, and board forming, to ultimately produce rock wool boards. It's worth noting that different manufacturers and production processes may use slightly different combinations of raw materials to meet the performance and standard requirements of specific products.hensive waterproofing performance for the building structure.

Smoke prevention and exhaust g

Smoke prevention and exhaust g

Burning performance level of g

Burning performance level of g

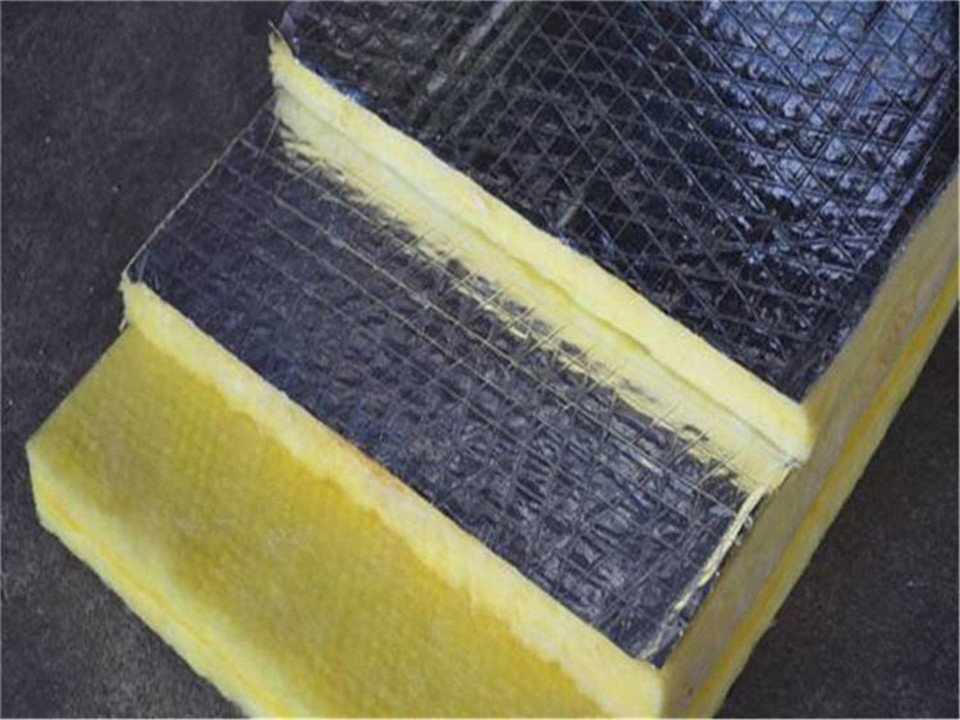

Insulation Related Product-Gla

Insulation Related Product-Gla

Can glass wool board replace f

Can glass wool board replace f